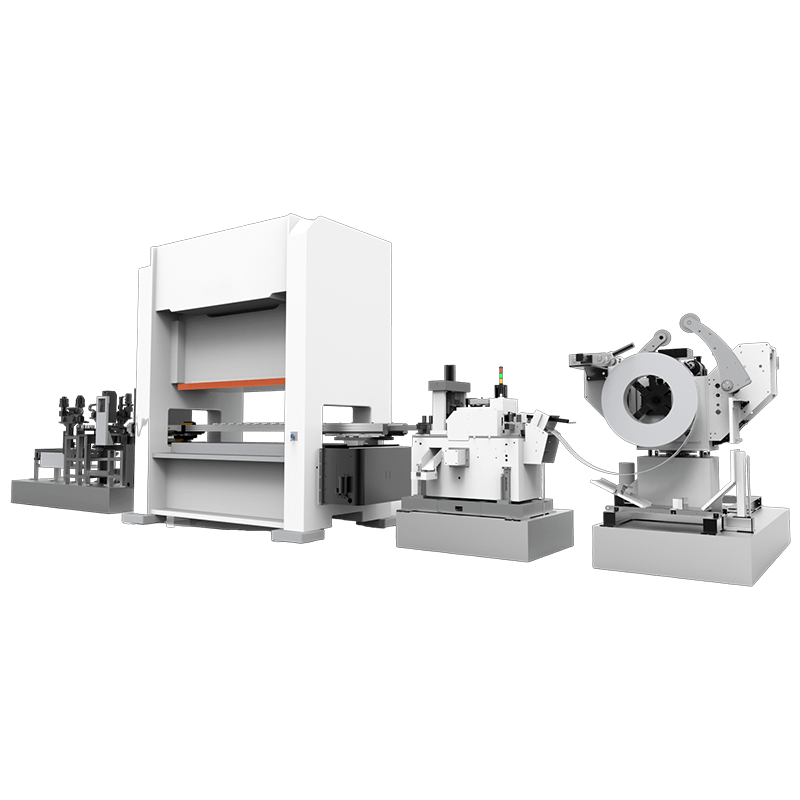

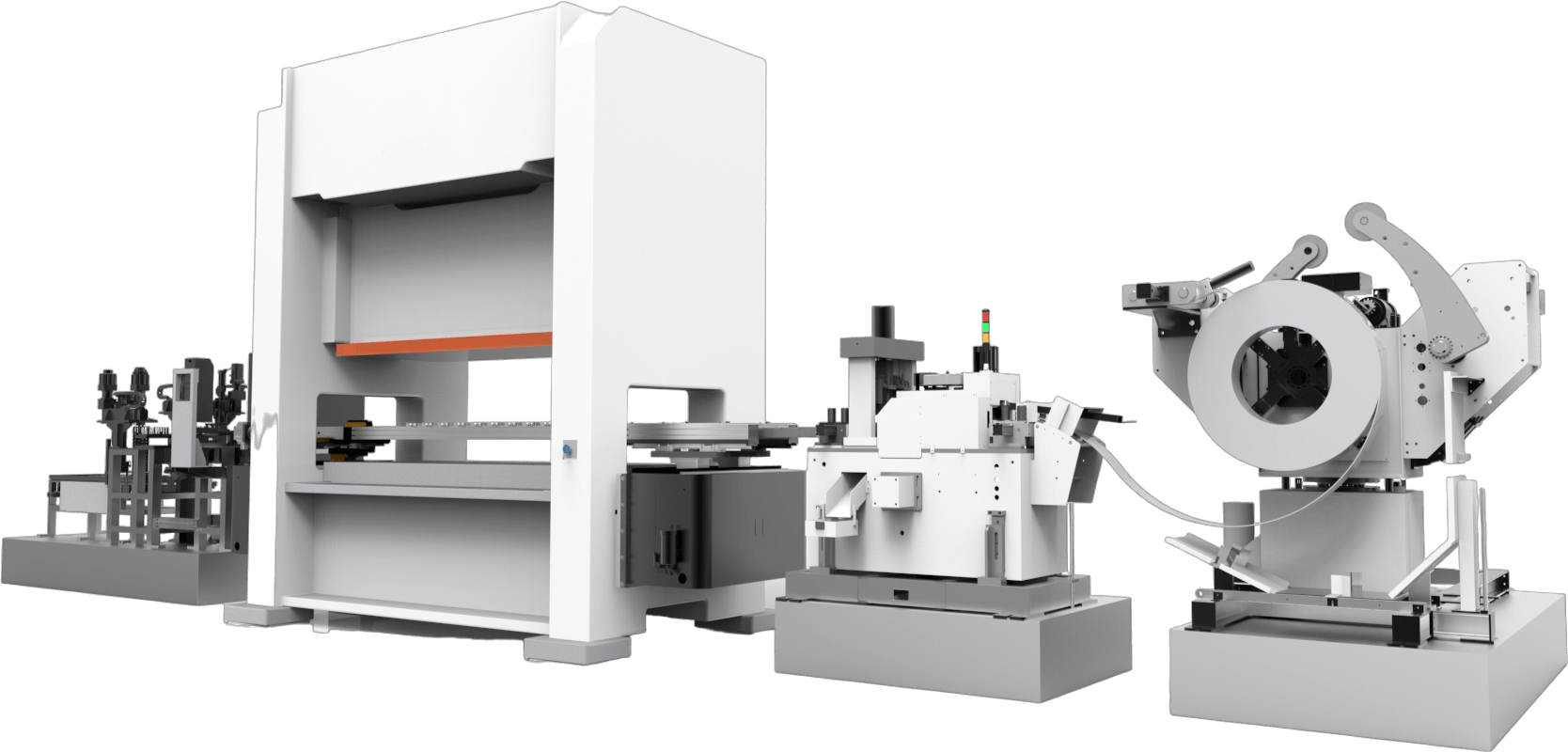

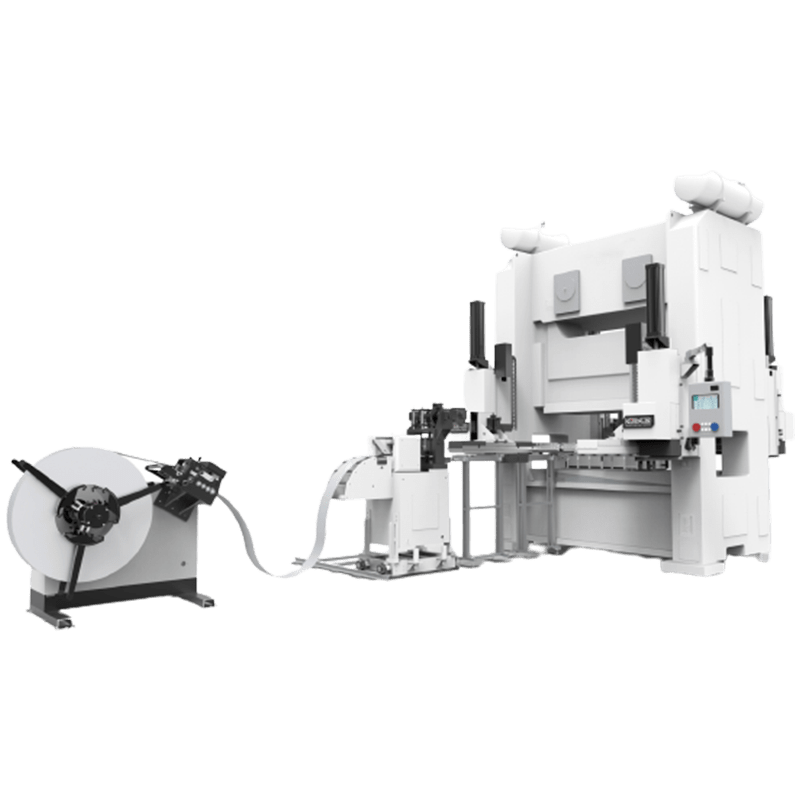

KSVT-3 Multi-station Servo Transfer

Perform multiple steps simultaneously, achieve low-cost investment but high-precision metal processing.

Perform multiple steps simultaneously, achieve low-cost investment but high-precision metal processing.

Perform multiple steps simultaneously, achieve low-cost investment but high-precision metal processing.

Provide high-quality and high-efficiency production, and meet various process processing requirements.

Suitable for industries such as computers, TFT/LCD monitors, electronics, automotive, and other medium to large-sized sheet metal stamping workpieces.

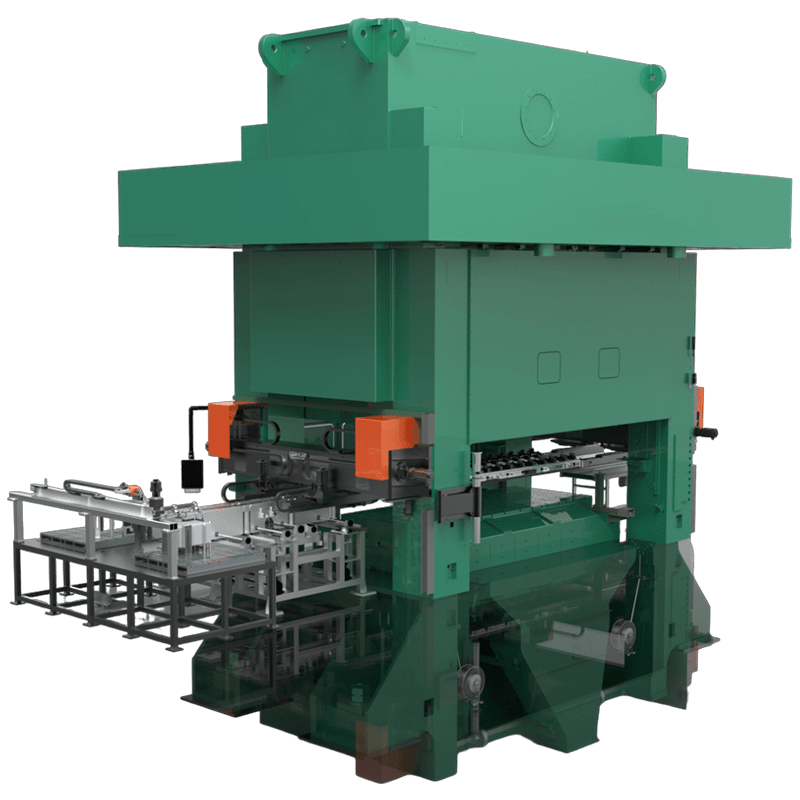

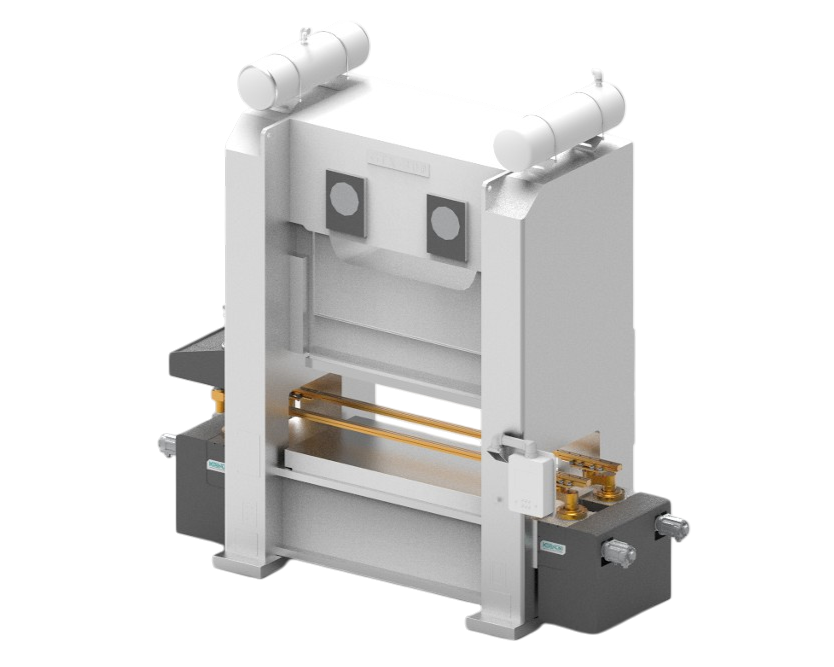

Standard equipment is all equipped with well-known brands to meet the requirements of precision

To achieve high-speed operation, effectively enhancing high rigidity and load capacity.

With Handwheel Simulation Function

Best Response Speed

High Inertia and High Torque Precision Servo

Heavy Load and Long Life Rail

With High Precision

C3-grade Precision Ground Ballscrews

Customized Ultra-Low Backlash Helical Gear/Rack

Automatic Lubrication System

Japan's Top 5 Bearing Brands

Electrical Control Box Thermostat (Cooling/Heating)

Precision stamping processing, production of high-quality metal parts.

Product specifications can be customized and according to yourrequirements.

Kuenlin would provides the optimal solutions to achieves maximum value and benefits.

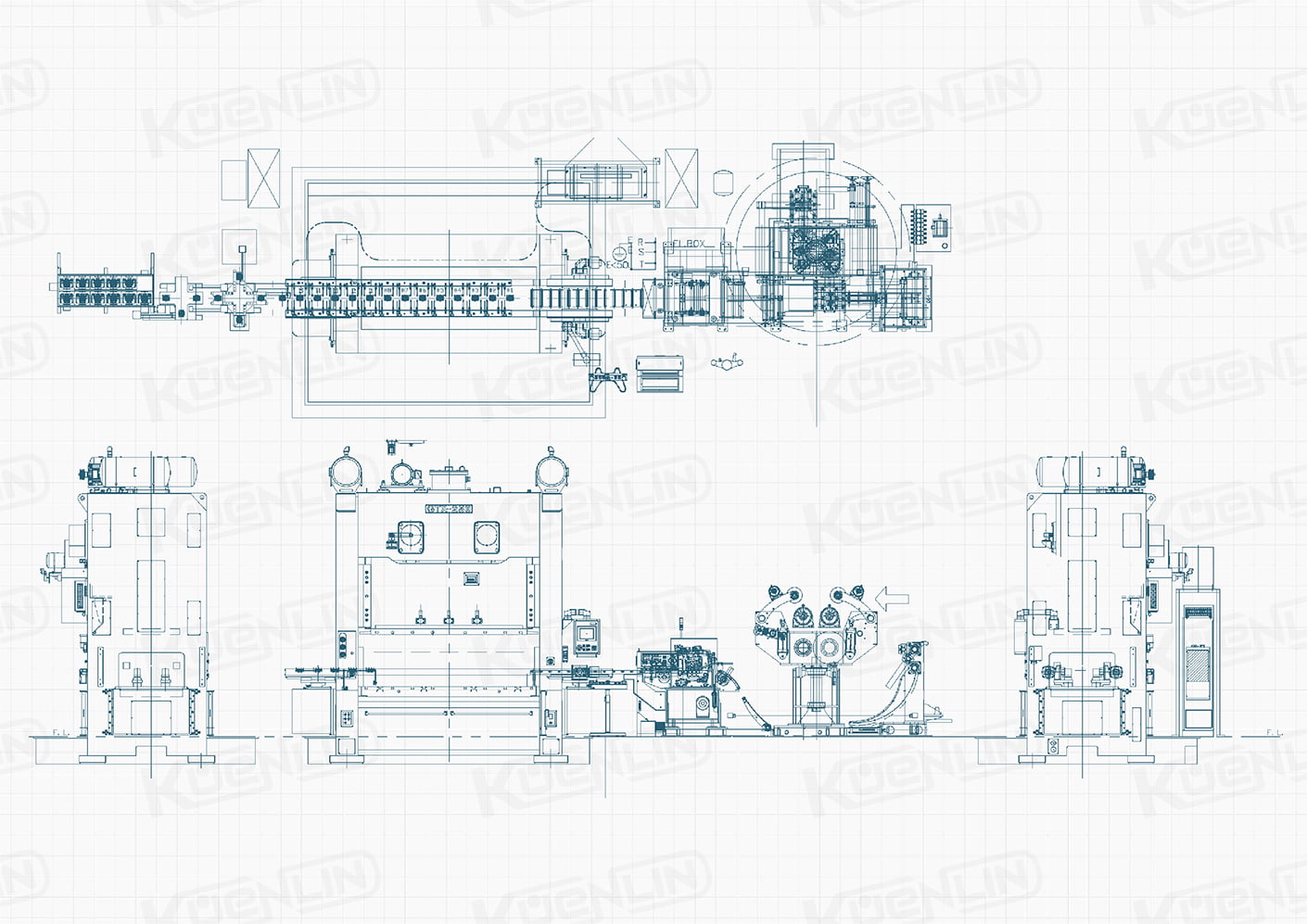

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Feeding machine

Destacker

Transfer Robot

One-stop Line Planning

Conveyor

Servo Transfer

Servo Transfer

Servo Transfer

Servo Transfer

Servo Transfer