- KUENLIN

- Solution

- Global Services

- Background

- Relationship

-

Our vision is to

collaborate with our customers to achieve intelligent manufacturing

and become the best trusted partner for our customers. -

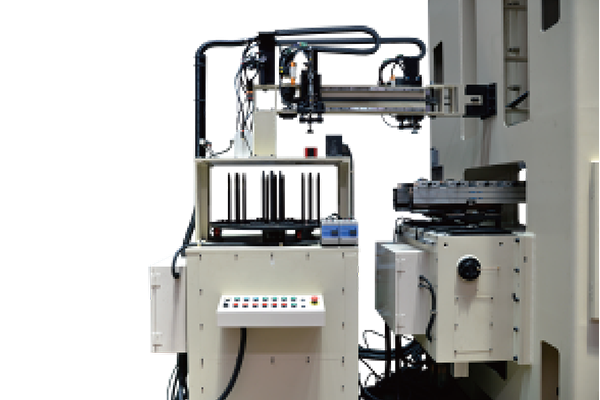

Kuenlin provides diversity automation solutions to the entire metalworking industry.

Sheet metal forming turnkey solutions

Stamping press

Automation transfer system

Blank production

Robot hand

Everything relevant with Stamping industry -

With multiple sales and service locations worldwide,

Kuenlin provides our customers with real-time and efficient service.

Additionally, we offer an online customer service platform to assist customers in tracking their equipment and production status -

Kuenlin inherits the Japanese tradition and engages in OEM/technical cooperation.

With a 70% market share in Taiwan's stamping industry,

we consistently achieve product development and technological innovation that leads the times.

Since 1979, we have been cooperating with Japanese companies to learn and inherit

their craftsmanship spirit and continuously improving technology. -

With rich production experience.

As a company that assists manufacturers, we strive to work closely with our customers as much as possible.

We offer a real-time online service platform to track machine and production status,

dedicated to developing intelligent stamping solutions that meet our customers' needs. -

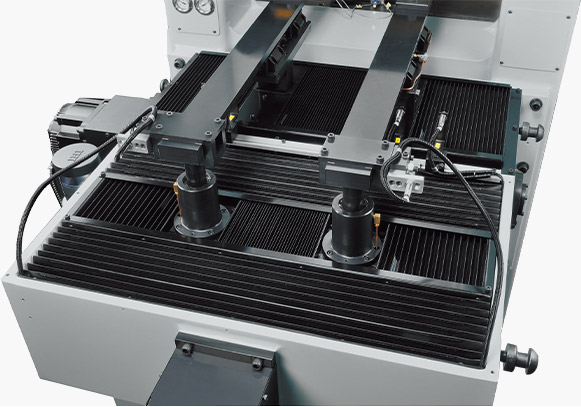

In Kuenlin's smart manufacturing plant environment,

our exclusive IOT visual inspection module helps customers track machine and mold health status,

operating analysis, and production status in real-time. T

his achieves thorough prevention of abnormalities and mold life cycle prediction. -

With its long and rich history, KL has accumulated extensive experience dating back to the early days of automation.

We offer valuable expertise and we are able to provide a wide range of products and customization

basic to customer requirements, delivering the perfect system for each customer.

- GLOBAL

- TAIWAN

-

01SHIMANO

-

02MABUCHI MOTOR

-

03TRANSMATIC

-

04SNAP ON

-

05ADITYA

-

06IFB

-

07SHIVAM

-

08UPSAM

-

09PANASONIC

-

10MITSUBISHI ELE

-

11HATARI

-

12ELARABY

-

01SDL

-

02Shye Shang

-

03RINNAI

-

04TAIWAN FU HSING

-

05G-SHANK

-

06SUMMER

-

07GRAND FORGING

-

08REPON SLIDES

-

09MABUCHI MOTOR

- Structure Patent

- Sesure Patent

- Security Patent

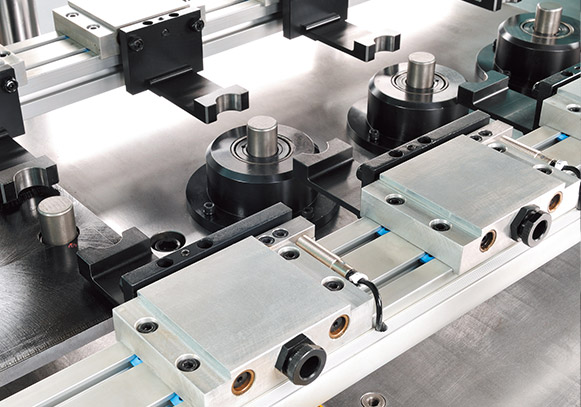

One-piece formed structure

- Uses high-precision C3 grade ballscrews.

- High-grade load-bearing linear slides greatly improve the smoothness of system.

- The integrated structure enhances equipment integration and stability.

-

01Taiwan(R.O.C.)

Patent Certificate Invention I 471190

Invention I 471190 -

02Taiwan(R.O.C.)

Patent Certificate Utility model M 457013

Utility model M 457013 -

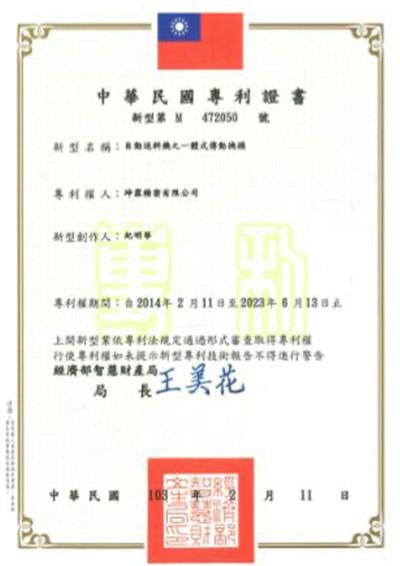

03Taiwan(R.O.C.)

Patent Certificate Utility model M 472050

Utility model M 472050 -

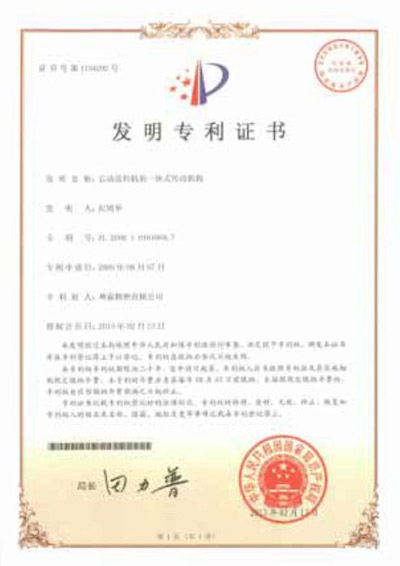

04Taiwan(R.O.C.)

Patent Certificate Invention ZL 2009 1 0161068.7

Invention ZL 2009 1 0161068.7 -

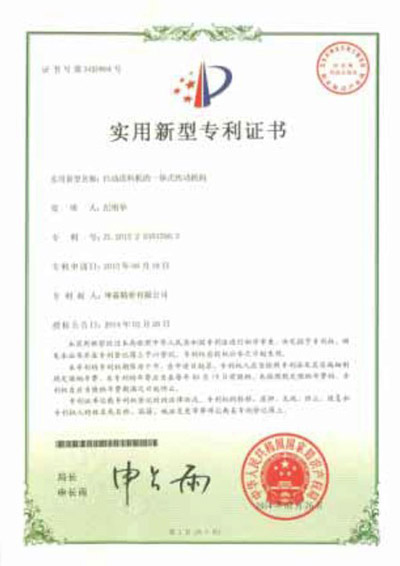

05Taiwan(R.O.C.)

Patent Certificate Utility model ZL 2013 2 0351706.3

Utility model ZL 2013 2 0351706.3 -

06Taiwan(R.O.C.)

Patent Certificate Invention ZL 2013 1 0243506.0

Invention ZL 2013 1 0243506.0

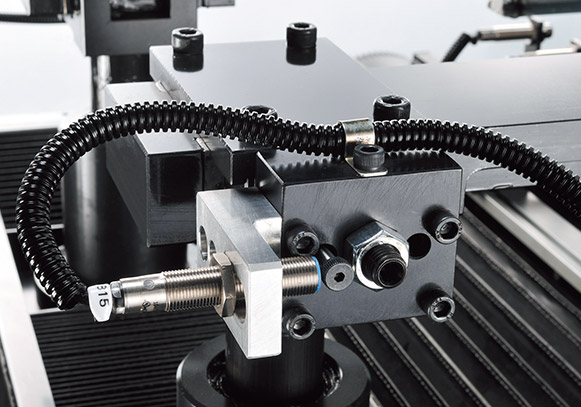

Gripper sensor

- Prevents defects caused by clamping errors or skewing.

- Uses an elastic device to sense the clamping process.

-

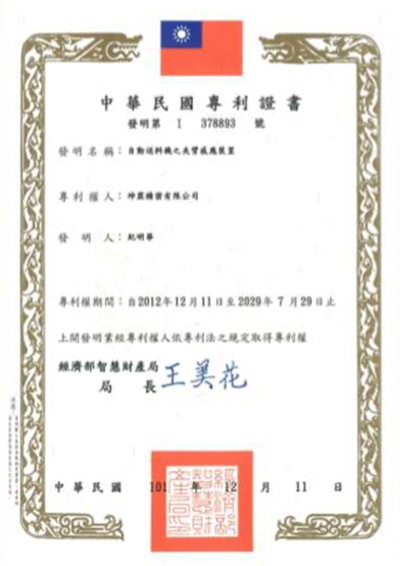

01Taiwan(R.O.C.)

Patent Certificate Invention I 378893

Invention I 378893 -

02China

Patent Certificate Invention ZL 2009 1 0159988.5

Invention ZL 2009 1 0159988.5

Overload Device

- Sensing resistance to ensure smooth transportation.

- Abnormalities prompt instant feedback for quick resetting and resuming operations.

-

01Taiwan(R.O.C.)

Patent Certificate Invention I 378892

Invention I 378892 -

02Taiwan(R.O.C.)

Patent Certificate Utility model M 502539

Utility model M 502539 -

03Taiwan(R.O.C.)

Patent Certificate Invention ZL 2009 1 0161066.8

Invention ZL 2009 1 0161066.8 -

04Taiwan(R.O.C.)

Patent Certificate Utility model ZL 2015 2 0090959.9

Utility model ZL 2015 2 0090959.9

- CUSTOMER

- KUENLIN

Our Customers

TAIWAN

SDL, Shye Shang, RINNAI, TAIWAN FU HSING, G-SHANK, SUMMER, GRAND FORGING, REPON SLIDES, MABUCHI MOTOR

Please contact Kuenlin customer service to find the nearest service center.

Headqurter

SERVICE POINTS

ASIA

China, Japan, Vietnam, India, Indonesia, Thailand

AMERICAS

Mexico, Brazil

EUPORE

Turkey, Czech Republic

Contact

Find the nearest service center

Please click " CONTACT US " , We will serve you as soon as possible.

-

Mech Transfer

Kuenlin was founded in 1986

1986-2009

1986

Kuen-Lin Precision was founded by Mr. Ji Minghua in 1986, inheriting the Japanese technical system. KL specializes in designing and manufacturing automation peripheral equipment for presses and cold forging.

-

Mech Transfer

The OEM mechanical transfer device was launched.

1986-2009

1991

The OEM mechanical transfer device was launched.

Kuen-Lin has a professional design team and upholds excellent product quality and good after-sales service. In this year, Kun-Lin entered the international market and became the only designated automation equipment supplier for a large international press manufacturer.

-

Mech Transfer

Cold forging transfer device.

1986-2009

1993

Cold forging transfer device.

In response to the characteristics of cold forging operations, our product simplifies production operations and significantly improves production efficiency while also providing higher durability and precision in machine positioning.

-

Servo Transfer

High-speed 3-axis transfer machine launched.

2010-NOW

2010

High-speed 3-axis transfer machine launched.

In this product phase, It has won multiple exclusive patented structures, high-speed, stable, and durable state.It is suitable for various processes of sheet metal, cold and warm forging. Since its release, it is still a popular and well-received star product.

-

Servo Transfer

7-axis servo transfer application device.

2010-NOW

2013

7-axis servo transfer application device

From high-speed material handling to feeding equipment;We offer one of the widest selections of complete metal forming systems. Kuenlin Precision can tailor production solutions for each customer's specific needs.

-

Servo Transfer

KSD-2 stacker and destacker machine

2010-NOW

2015

KSD-2 stacker and destacker machine

Continuous loading and unloading, and workpiece placement accuracy, maximizing workpiece storage space and production efficiency.

-

Servo Transfer

Single-station cold forging transfer equipment

2010-NOW

2015

Single-station cold forging transfer equipment

By streamlining production processes, it significantly improves production efficiency and enhances the positioning accuracy and durability of the machine.

-

Servo Transfer

8-axis servo transfer for hot forging

2010-NOW

2016

8-axis servo transfer for hot forging

Suitable for multi-process thin steel sheets and continuous die parts, simultaneously completes multiple processes and achieves high-efficiency automated production lines.

-

New Factory

Kuenlin opened a new factory in 2021

2010-NOW

2021

In 2021, under the leadership of Chairman Ji and Vice President , Kuenlin Precision achieved significant growth in performance. In order to meet the wider market demand, Kuenlin Precision opened a new factory in 2021 to provide leaner services and turnkey solutions. Looking forward to the future.

- 1986

- 1991

- 1993

- 2010

- 2013

- 2015

- 2015

- 2016

- 2021

- Automotive

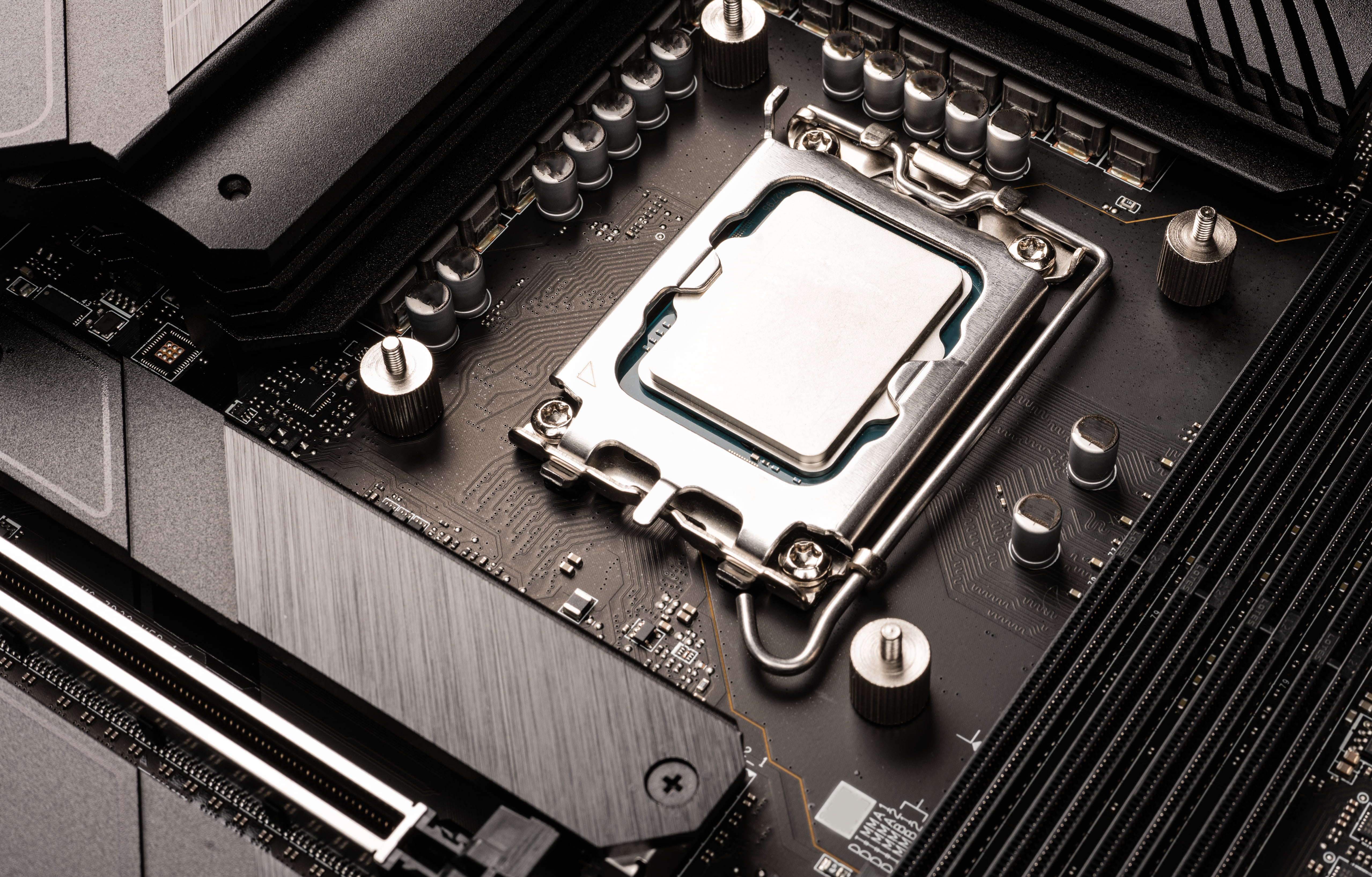

- Electronics

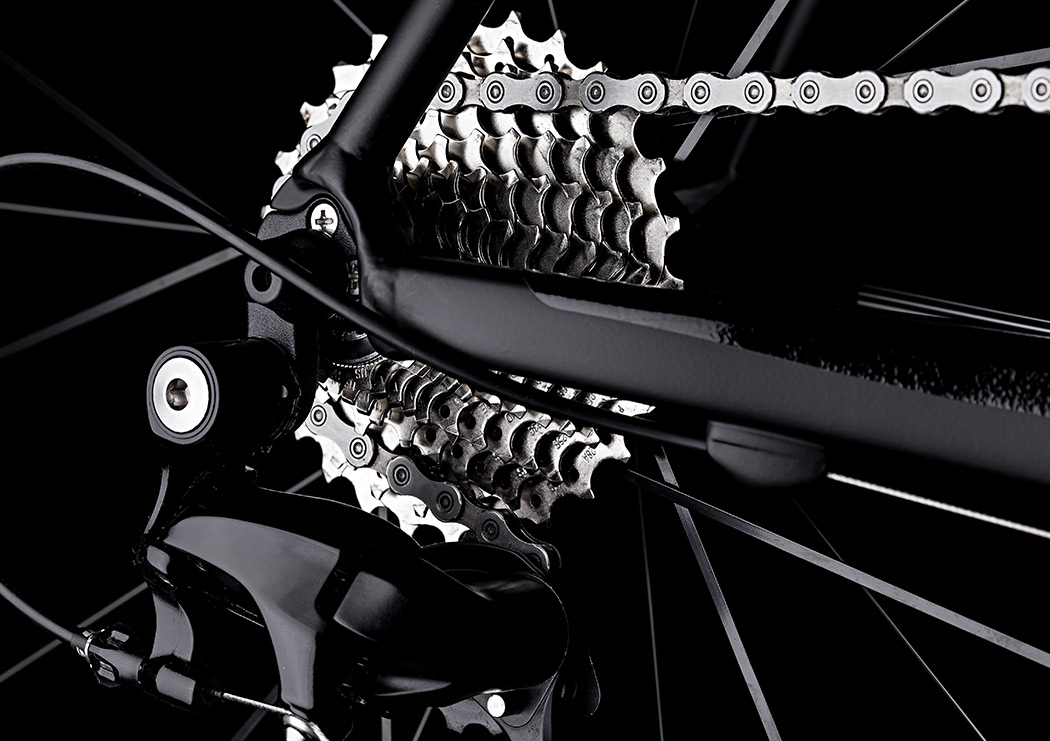

- Vehicle

- Appliance

- Hardware

Kuenlin provides extensive automation solutions for the automotive industry, and we can assist you in producing and processing various products, including automotive body panels, automotive sheet metal parts, door frames, brackets, safety belt components, electric motor housings, safety airbag components, exhaust pipes, steering gears, reinforcing plates, umbrella gears, bumper bars, oil sumps, crankshafts, fuel injectors, and more. Kunlin can plan the most suitable mold type and automation process according to customer needs.

Kuenlin is an expert in metal stamping automation equipment, and the 3C (computer, communication, and consumer electronics) industry is also a market that extensively uses stamped parts, such as computer heat sinks, casings, brackets, chassis, panels, protective covers, display backplates, electrode bridges, connectors, electromagnetic shielding covers, terminals, HDMI, satellite parts, and more.

The production and development of motorcycle parts are closely related to the stamping process, and we have assisted many transportation manufacturers in producing large quantities of chain links, brake pads, sprockets, chain shifters, brake levers, flywheels, shock absorbers, crankshafts, hubs, gearboxes, brackets, handlebars, rims, and more.

Kuenlin provides stamping automation equipment that helps you produce home appliance parts using the most efficient processes. Examples of these parts include air conditioner housings, TV panels, range hood shells, motor casings, machine boxes, gas stove accessories, fan blades, water tanks, panels, bases, control boxes, refrigerator components, and washing machine components.

Door locks, hinges, springs, latch bolts, utensils, water filter shafts, bottle caps, stainless steel cutlery.